Image: Klaus Achterhold / TUM

The children’s game “I spy with my little eye …” is the everyday experience at the airport luggage control, for the dentist starting a root channel therapy, and for the radiologist examining CT-images. With X-rays one can view non-destructively inside objects or patients.

Today, there are about 1500 computer tomographs in German hospitals with which physicians obtain three-dimensional images of the inside of a person’s body. The spatial resolution is in the range of 0.5 mm to 1 mm. While this resolution is sufficient for most medical applications, the fields of non-destructive testing and biomedical research require a significantly higher resolution.

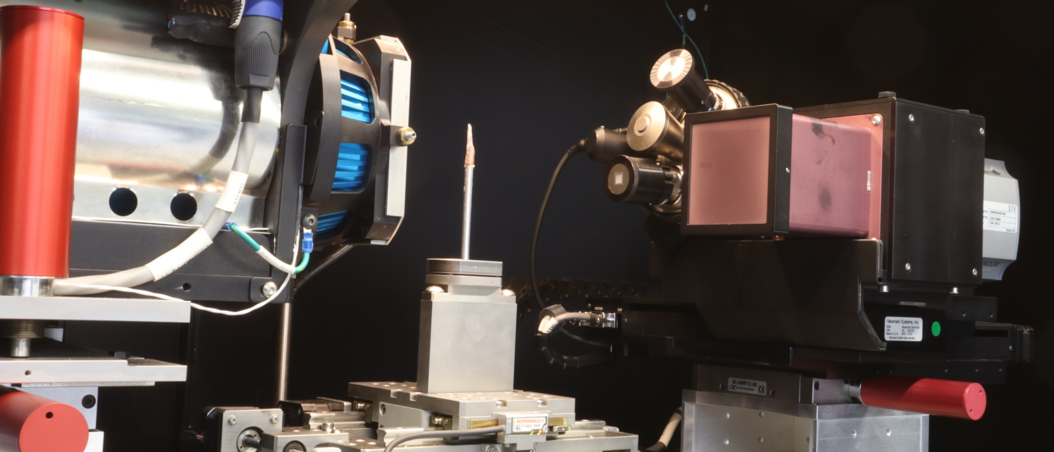

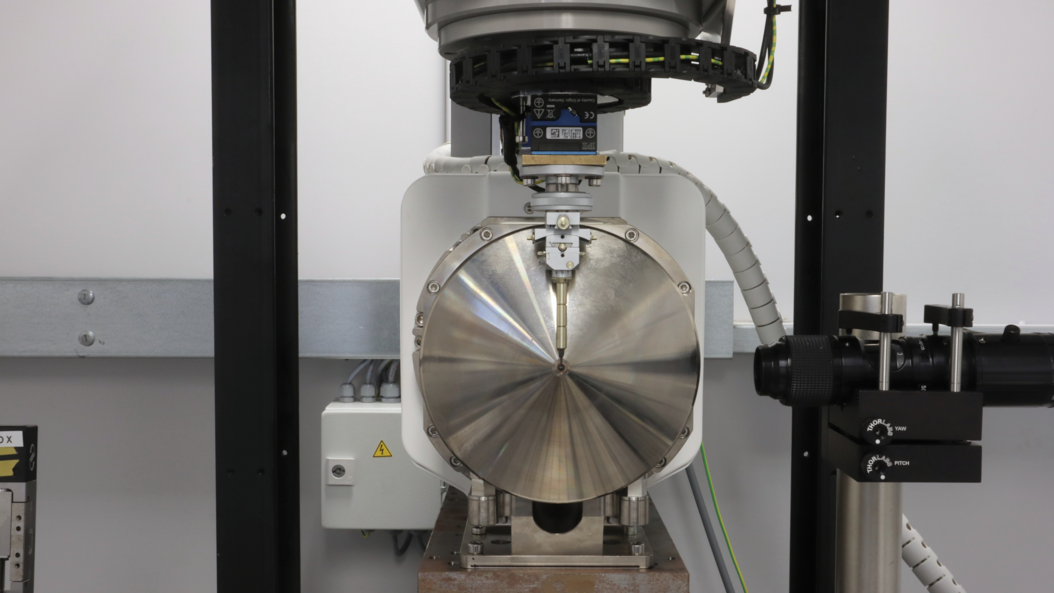

For this purpose, the X-ray laboratory of MIBE hosts two commercial microCT devices (“versaXRM 500” of the company ZEISS and “v|tome|x s 240” of GE as well as a nanoCT setup for extreme spatial resolution developed by the Chair of Biomedical Physics. Together, these devices cover a range of spatial resolution from about 0.1 µm (nanoCT) to 3 µm.

The high spatial resolution is achieved by geometric magnification with a divergent X-ray beam. To achieve this, a sample is positioned as close as possible to a very small focal spot of an X-ray tube.

The X-ray beam is attenuated within a sample depending on the spatially varying composition of its material. The X-ray light thus generates a projection image of the sample onto a two dimensional detector. About 1500 projection images are collected during a 360° rotation of the sample. These images are then combined to generate three-dimensional images.

The total time of data collection depends on the size of the sample, its material, and the required spatial resolution. A measurement can take between some minutes and a few days.

Image: Klaus Achterhold / TUM

Image: Klaus Achterhold / TUM

More Information

nanoCT

[1] M. Müller, I. de Sena Oliveira, S. Allner, S. Ferstl, P. Bidola, K. Mechlem, A. Fehringer, L. Hehn, M. Dierolf, K. Achterhold, B. Gleich, J. U. Hammel, H. Jahn, G. Mayer, and F. Pfeiffer, Myoanatomy of the velvet worm leg revealed by laboratory-based nanofocus X-ray source tomography, PNAS (2017) 114 (47) 12378-12383, https://doi.org/10.1073/pnas.1710742114

[2] S. Ferstl, T. Schwaha, B. Ruthensteiner, L. Hehn, S. Allner, M. Müller, M. Dierolf, K. Achterhold, and F. Pfeiffer, Nanoscopic X-ray tomography for correlative microscopy of a small meiofaunal sea-cucumber, Scientific Reports (2020) 10:3960, https://doi.org/10.1038/s41598-020-60977-5

microCT (versaXRM)

[3] M. Busse, M. Müller, M. A. Kimm, S. Ferstl, S. Allner, K. Achterhold, J. Herzen, and Franz Pfeiffer, PNAS 115 (10) (2018) 2293-2298, Three-dimensional virtual histology enabled through cytoplasm-specific X-ray stain for microscopic and nanoscopic computed tomography, https://doi.org/10.1073/pnas.1720862115

[4] P. Bidola, K. Morgan, M. Willner, A. Fehringer, S. Allner, F. Prade, F. Pfeiffer, and K. Achterhold, Application of sensitive, high-resolution imaging at a commercial lab-based X-ray micro-CT system using propagation-based phase retrieval, Journal of Microscopy, Vol. 266, Issue 2 2017, pp. 211–220, https://doi.org/10.1111/jmi.12530

microCT (v|tome|x)

[5] D. Petz, M.J. Mühlbauer, A. Schökel, K. Achterhold, F. Pfeiffer, T. Pirling, M. Hofmann, A. Senyshyn, Heterogeneity of graphite lithiation in state-of-the-art cylinder- type Li-ion cells, Batteries & Supercaps; https://doi.org/10.1002/batt.202000178

[6] H. My Bui, R. Fischer, N. Szesni, M. Tonigold, K. Achterhold, F. Pfeiffer, O. Hinrichsen, Development of a manufacturing process for Binder Jet 3D printed porous Al2O3 supports used in heterogeneous catalysis, Additive Manufacturing 50 (2022) 102498, https://doi.org/10.1016/j.addma.2021.102498